Subject_02_Final 3D print model

The final print model is changed. The print and print program can not translate the my STL file because the file has too many polygon and vertex. So, I delete inner bone part and resize before stretch ver. The height can affect the print time, so I can not print long one.

The printing

With supporter

The printing work takes about 35hours and the melting supporter work takes a day. But the result's resolution is better than I think and the thickness is not too sharp. This is final model pic.

Pic_01

Pic_02

Pic_03

Pic_04

Pic_05

Pic_06

Pic_07

Pic_08

Pic_09

Pic_10

Sunday, December 8, 2013

Sunday, December 1, 2013

BREAK:IN_12

Subject_02_Final render

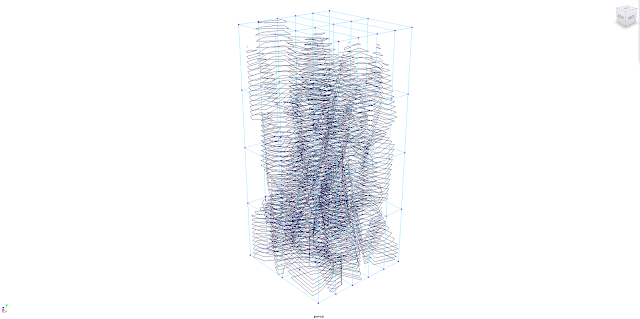

The printing is now working. And this is the render scene for doc or another use. I think about the variety of another alternative in bone solid parts. The random option or stacking option or column option has. I render whole scene with the concept will be revealed well specially.

Final model

I shot the scene for the concept is revealed well. The whole shape is square and the fragments are originated from that. and the whole parts make cube's time and shape anatomy.

The side view_01

The side view_02

The side view_03

This is extra scene. After taking shot these scene, I think the object resemble to building or some structure for human. The stacked bone parts make floor and the fragments frames make structure. I do not know exactly, this method or some changed way have many possibility for new making form in real life or design I think.

The perspective view_01

The perspective view_02

Bird's view

Closed view_01

Closed view_02

Closed view_03

Special one

The printing is now working. And this is the render scene for doc or another use. I think about the variety of another alternative in bone solid parts. The random option or stacking option or column option has. I render whole scene with the concept will be revealed well specially.

Final model

I shot the scene for the concept is revealed well. The whole shape is square and the fragments are originated from that. and the whole parts make cube's time and shape anatomy.

The top view

The side view_02

The side view_03

This is extra scene. After taking shot these scene, I think the object resemble to building or some structure for human. The stacked bone parts make floor and the fragments frames make structure. I do not know exactly, this method or some changed way have many possibility for new making form in real life or design I think.

The perspective view_01

The perspective view_02

Human view

Closed view_01

Closed view_02

Closed view_03

Special one

Sunday, November 24, 2013

BREAK:IN_11

Subject_02_For final printing

Making fragments skin with frame

Making one shape

Stacking inner parts

Connecting outside parts

Inner structure

This is final shape for printing light render ver. The outside frame is more thicker because the print may be lost sharpness part or thin part. But I think the frame is more thin than now is best.

Whole parts

Side view

Perspective view

For final print, I control the whole shape because the sharpness part may be lost in printing. So, the dropping situation is expressed by just the stretch whole shape vertically. And the each fragments have inner structure like a bone parts, something like a break:in anatomy.

Stretch the shape

stacking structure by projected line

The final shape will be more organic and whole parts are connected. And the all parts will be one closed surface for real printing. So, I trim and control the surface and vertex manually step by step.

Stacking inner parts

Connecting outside parts

Completed shape

This is final shape for printing light render ver. The outside frame is more thicker because the print may be lost sharpness part or thin part. But I think the frame is more thin than now is best.

Side view

Perspective view

Sunday, November 17, 2013

BREAK:IN_10

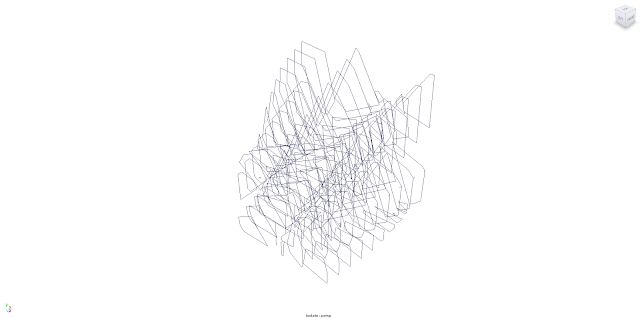

Subject_02_New Form making method

Project line

Extract the line

Form changing

Connecting each level

Stacking shape up

Lowfied surface

Shape with hole

I change the method for making form slightly. This time, I try to express for reason both dropping accident and cube form. So, I project the line to fragments pile for sewing with same axis. With this one, reform the shape for making scene that dropping accident with gravity. The size of surface will express the dropping velocity.

Extract the line

Form changing

Adapt gravity situation

And I use these parts, make the bone shape something for complete concept "BREAK:IN". The bone shape will be metaphor the origin, or the reason something like a cube anatomy. For making shape, I will connect each level and make the bone shape each fragments.

Stacking shape up

Lowfied surface

Shape with hole

Perspective

Sunday, November 10, 2013

BREAK:IN_09

Subject_02_Form Making

I use the sewed 100 lines, make cube with dividing three parts. Each parts are making original form, cube and each fragments are sewed with same z axis.

Modeling

Render_01

I use the sewed 100 lines, make cube with dividing three parts. Each parts are making original form, cube and each fragments are sewed with same z axis.

Three parts for making original shape

And I use these parts, make the bone shape something for complete concept "BREAK:IN". The bone shape will be metaphor the origin, or the reason something like a cube anatomy.

First part

First section

Extrude and making form

Working pic_01

Working pic_02

For testing in real 3d print, I prepare small parts of this first section. This has closed surface for real print and I get rid of all slice point or thin line for completed testing.

Render_01

Render_02

Subscribe to:

Posts

(

Atom

)